- Product introduction

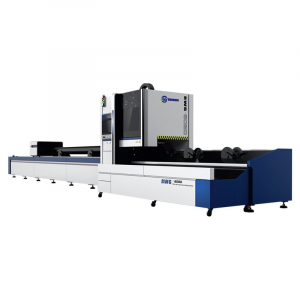

The special pipe laser cutting machine consists of 7 shafts Feature.

It can realize the cutting of round,square,rectangular and elliptical pipes.

It can realize the one-time forming and processing of 6-meter

pipe, and can be equipped with 9-meter and 12-meter pipe cutting

machines with different pipe lengths and diameters.

The equipment is matched with feeding shaft and pulling shaft

which can greatly reduce the waste of processing tailings.

It can cut multiple pipes with different directions and diameters on the main

pipe.

It can cut variable angle groove surface.

It is known as pipe cutting machine and material expert in the industry.

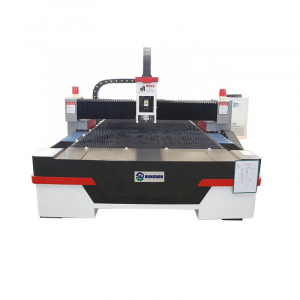

Best laser cutting machine

Applicable for high-speed cutting on various metal plates or tubes such as

S/S, carbon steel, galvanized sheet, electrolytic plate, aluminum plate, steel,

brass, alloy plate, rare metals and other materials.

Laser cutter for thin metal

Widely used in kitchen appliance, electric control box, high-resolute device,

mechanical equipment, electrical equipment, lighting, posters, auto parts,

display equipment, hardware and metal processing.

- Our Advantage

The structure is simple and stable, with good airtightness and movement characteristics. It can clamp square tubes, round tubes, oval tubes, flat tubes, triangle tubes, I-beams, I-beams and other materials.

Equipped with tail material processing function, the two chucks internally support and clamp the tail material at least 100mm. The cutting tail material is when the front chuck is opened, and the rear chuck is opened before the rear chuck is opened, and the cutting inside the chuck is minimized. , While ensuring the cutting precision of the tailings products.

The clamping force can be accurately controlled and adjusted according to different pipe diameters and wall thicknesses. The adjustment accuracy is ±1kg clamping force. The clamping control force for thin-walled materials has obvious effect, avoiding the deformation of the pipe clamp during the production process and the release of the clamp. Phenomenon, at the same time, aluminum alloy pipes, stainless steel pipes, and surface-treated pipes can prevent the surface from being pinched.

- Machine details

1.The main frame is made of full steel plate welding to ensure that the model is

stable for a long time without deformation

2.The bed is annealed by a large annealing furnace

3.The bed is formed once through imported gantry milling

4.Using the gantry rack double guide rail, double servo drive structure

5.Improve the stability and rigidity of the Y-axis cross-beam

6.Ensure the high accuracy and high dynamic performance of the Y-axis

crossbeam movement

7.The Y-axis beam runs at high speed and smoothly, greatly reducing the gas

consumption

1. This cutting head has strong advantages in the

application of medium power large format

fiber laser cutting.

2. The internal structure of the laser head is

completely sealed, which can avoid the dust

pollution of the optical part.

3. The laser head is adjusted by two points, and the

focus is driven by the imported motor in the

perforated side Face efficiency is significantly improved.

4. The protective lens is installed in the drawer type

for convenient replacement.

5. Auto-adjust the spot size.

6. A kinds of lasers with QBH connector.

Single-module continuous fiber lasers are used as industrial applications

Product, is a high efficiency, high beam quality of the single module

fibre laser. Mainly used in punching, cutting and welding And so on. In this

main lose to enter the article: this.(1) Please at high beam mass Your text.

(2) high power, high efficiency (3) high reliability, long life

(4) compact, solid packaging (5) extended programming joggle

| ||||||||||||||||||||||||||||||||||||||||||||||||