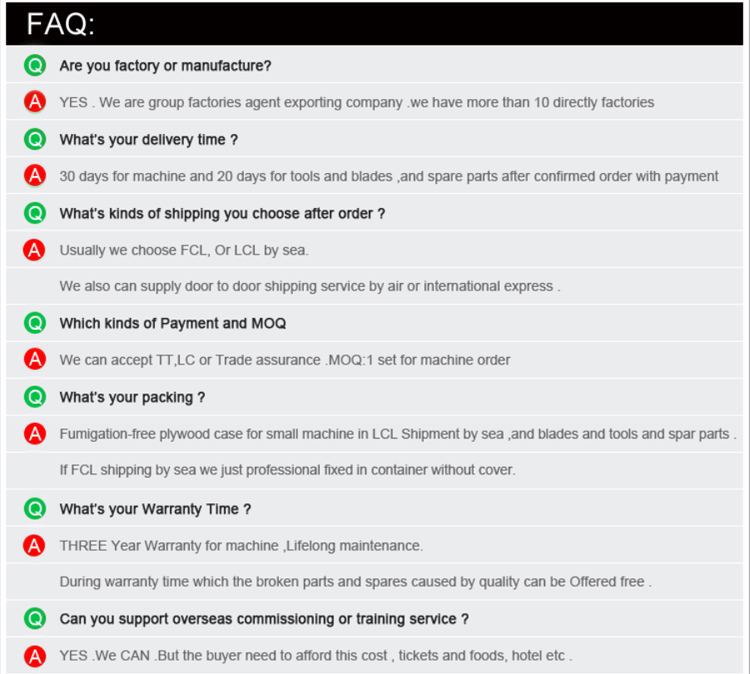

Essential details

- Slider Stroke (mm):

- 170 mm

- Automatic Level:

- Fully Automatic

- Throat Depth (mm):

- 400 mm

- Machine Type:

- panel bender

- Length of Working Table (mm):

- 1000/1400/2000/2500

- Width of Working Table (mm):

- 2000 mm

- Dimension:

- 4400*2100*2900

- Condition:

- New

- Place of Origin:

- Anhui, China

- Brand Name:

- RONGWIN

- Material / Metal Processed:

- Brass / Copper, Stainless steel, Carbon steel, Aluminum

- Automation:

- Automatic

- Extra Services:

- End Forming

- Year:

- 2022

- Weight (KG):

- 12000

- Motor Power (kw):

- 38 kw

- Key Selling Points:

- Automatic

- Warranty:

- 3 years

- Applicable Industries:

- Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Retail, Construction works , Energy & Mining, Advertising Company

- Showroom Location:

- Egypt, Canada, Turkey, United Kingdom, United States, France, Germany, Viet Nam, Saudi Arabia, Indonesia, Pakistan, India, Russia, Thailand, South Korea, Chile, UAE, South Africa, Japan, Malaysia, Australia

- Marketing Type:

- Hot Product 2022

- Machinery Test Report:

- Provided

- Video outgoing-inspection:

- Provided

- Warranty of core components:

- 1 Year

- Core Components:

- Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox

- Name:

- Automatic Steel Panel Bender

- Usage:

- Metal Sheet Bending

- Keyword:

- CNC Panel Bender

- Voltage:

- 220V/380V/415V/440V/customized

- Axis:

- 9 axis, 13 axis, 15 axis

- Motor:

- Servo Motor

- Weight:

- 12000KG

- Linear Guide:

- Taiwan HIWIN

- Reducer:

- Japan Shinpo

- Brand:

- Rongwin

Supply Ability

- Supply Ability

- 20 Set/Sets per Month

Product Description

Rongwin panel bender bending center adopts a full servo system. Unlike traditional bending machines, the bending machine mold needs to be pressed down against the fixed part of the bending machine, but the bending work is completed by the blade. During the bending process, the plate The material holder fixes the plate. The blade can be bent up or down in different shapes. First, one side is bent outward, and then it is automatically bent inward. These different actions are controlled by the servo electric drive device, which can ensure the highest positioning accuracy in the bending sequence and bring the best bending effect.

Industry Application

*Food machinery, goods and household appliances

*Steel furniture, sheet metal and warehouse

*Electrical cabinet

*Steel door and frame

*Elevators and escalators

*Generators

*Hospital and laboratory equipment

*HVAC

*lighting device

Suction cup type

Press arm type

Detailed Images

Rongwin's brand-new self-developed full-servo CNC system has seamless and coherent movements, leading the world in work efficiency, and independently designed hardware circuit boards with lead-free soldering and surface immersion gold processing technology, which is stable and durable.

Abundant interfaces are reserved to support CNC, PLC, robot, etc.

Provide partners with free lifetime system upgrade services.

Machine frame

Our equipment is designed and produced according to the high precision machine standards,the main lathe bed adopts high grade castings,and the casting and weld assembly are all subjected to strict stress relieving process,also,they are producted integrated by ultra precision machine tool, finally, with the stictly control by our high precision detector, our machines can ensure the higher accuracy,higher stability and higher rigidity during there long-time running period.

The Nanjing technology 8020 heavy-duty grinding-grade screw is selected, which has more stable transmission and higher precision.

The Nanjing heavy-duty high-precision P3 grade 55 roller-type linear guide is selected, which has a larger bearing capacity and higher precision.

Select NACHI original high-load ball screw injection molding machine special bearings, bearing ball diameter up to 16mm.

Bending Tools

The upper and lower bending knives (A, D) perform upward or downward bending during work.

The upper pressing knife (B) and the lower pressing knife (C) clamp the sheet during bending. Works simultaneously with the bending knife to hold and bend the sheet accurately and efficiently

Imported slow wire process, higher consistency, the precision can reach 0.006mm through segmented upper pressing, the overall heat treatment and ultra-cryogenic process, the hardness is higher and more wear-resistant.

RONGWIN panel bender adopts a universal bending die, only one set of die can be used to complete the bending of various shapes, and users do not need to customize another die. The equipment department can easily realize the bending requirements of arc 'dead edge, back shape, closed type and other complex types of sheet metal bending. ’

Automatic Load / Unload Solution

The system reserves a wealth of Industry 4.0 interfaces, which can be connected to the robotic arm to realize automatic loading and unloading.

With RONGWIN self-propelled manipulator, it has the same control system as the panel bender, and there is no need for secondary programming to replace the workpiece. The system automatically generates the motion of the robotic arm according to the bending instructions, which is more efficient and has better coordination.

Machine parameters

Max. bending speed | 0.2 s/time |

Max. bending width | 1000mm/1400mm/2000mm/2500mm |

Bending height | 170 mm |

Average power | 1.5 kw |

Max. bending thickness | UTS 580N/mm2 Stainless steel 1.5 mm |

UTS 410N/mm2 Carbon steel 2 mm | |

UTS 265N/mm2 Aluminum 3 mm | |

Min. bending thickness | 0.35 mm |

Best Selling

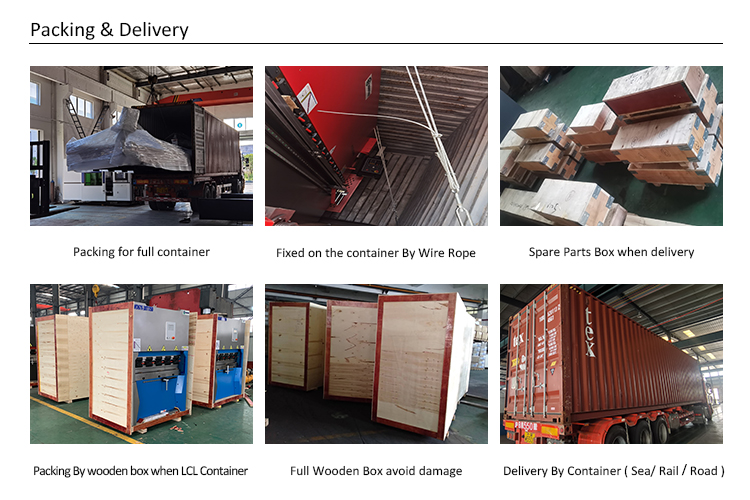

Packing & Shipping

Company Introduction

Nanjing RONGWIN Machinery Technology Co.,Ltd is located in Zijin Technology Center, Lishui Economic Development Zone,Nanjing,Jiangsu,China (Mainland). We are professional one-stop metal fabrication solution supplier in China . Our factory with more than 30 years manufacturing experience . All of our machines meet CE and ISO Certificate .

Our main product are:

1)Metal Cutting Machines :Fiber Laser Cutting Machine ,Hydraulic Shearing Machine,V-Grooving Machine,Plasma Cutting Machine,Waterjet,Notching Machine,Tube Cutting Machine,Scrap Metal Shredder Machine ,

2)Metal Bending Machines: Hydraulic Press Brake, CNC Panel Bender, Hydraulic Plate Rolling Machine,Hydraulic Tube Bending Machine,Hydraulic Profile Bending Machine,

3)Metal Forming Machines :Hydraulic Press ,Power Press,Ironworker, HVAC Dust Machine,Welding Machine,

4)Spare Parts for Metal Working Machines: Press Brake Tooling,Blades, Molds and other spare parts etc Please check our website for more details . We hope to establish long time business relationship with esteemed company .and will try our best to support you and your business .