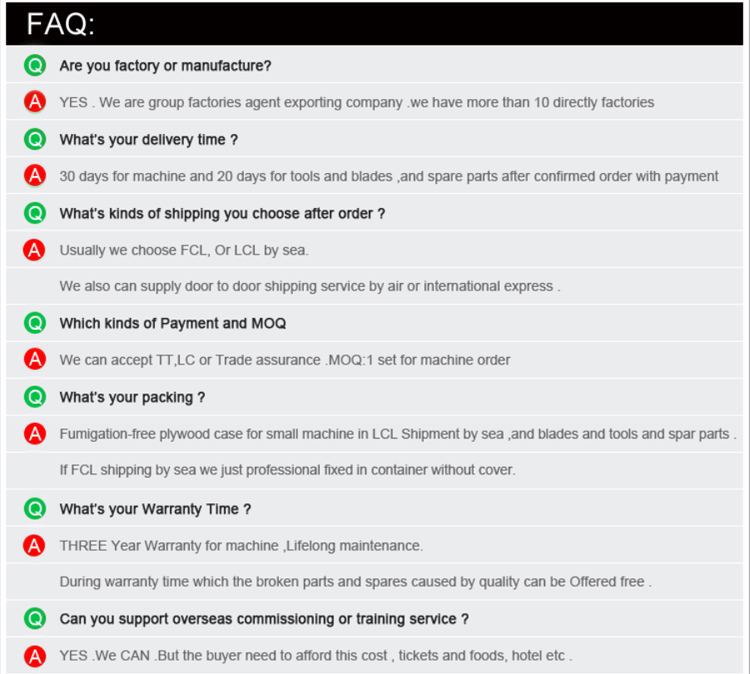

Essential details

- Slider Stroke (mm):

- 175 mm

- Automatic Level:

- Fully Automatic

- Throat Depth (mm):

- 400 mm

- Machine Type:

- panel bender

- Length of Working Table (mm):

- 1300/1600/2000

- Width of Working Table (mm):

- 2000 mm

- Dimension:

- 4800*2100*3000

- Condition:

- New

- Place of Origin:

- Anhui, China

- Brand Name:

- Rongwin

- Material / Metal Processed:

- Stainless steel, Carbon steel, Aluminum

- Automation:

- Automatic

- Extra Services:

- End Forming

- Year:

- 2023

- Weight (KG):

- 12000

- Motor Power (kw):

- 1.5 kw

- Key Selling Points:

- Automatic

- Warranty:

- 3 years

- Applicable Industries:

- Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Construction works , Energy & Mining, Advertising Company

- Showroom Location:

- Egypt, Turkey, United States, Germany, Saudi Arabia, Indonesia, India, Russia, Thailand, South Korea, Chile, UAE, South Africa, Japan, Malaysia, Australia

- Marketing Type:

- New Product 2023

- Machinery Test Report:

- Provided

- Video outgoing-inspection:

- Provided

- Warranty of core components:

- 1 Year

- Core Components:

- Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox

- Name:

- Competitive Price Press Brake Bending Machine for Kitchen Cabinet

- Usage:

- Metal Sheet Rolling Bending

- Keyword:

- Panel Bender

- Voltage:

- 220V/380V/415V/440V/customized

- Axis:

- standard 9 axis, support 16 axis

- Motor:

- Servo Motor

- Linear Guide:

- Taiwan HIWIN

- Reducer:

- Japan Shinpo

- After-sales Service Provided:

- Field installation, commissioning and training

Supply Ability

- Supply Ability

- 20 Set/Sets per Month

Product Description

CNC Press Brake 400 Panel Bender Press Brake Bending Center Machine with Low Price

Rongwin panel bender bending center adopts a full servo system. Unlike traditional bending machines, the bending machine mold needs to be pressed down against the fixed part of the bending machine, but the bending work is completed by the blade. During the bending process, the plate The material holder fixes the plate. The blade can be bent up or down in different shapes. First, one side is bent outward, and then it is automatically bent inward. These different actions are controlled by the servo electric drive device, which can ensure the highest positioning accuracy in the bending sequence and bring the best bending effect.

Industry Application

*Food machinery, goods and household appliances

*Steel furniture, sheet metal and warehouse

*Electrical cabinet

*Steel door and frame

*Elevators and escalators

*Generators

*Hospital and laboratory equipment

*HVAC

*lighting device

Detailed Images

Rongwin’s new independent research and development of 9-axis (supporting up to 16-axis concurrency) concurrent linkage full-servo CNC system, seamless action, coherence, global leading work efficiency, independent design of lead-free soldering of hardware circuit boards, surface immersion gold processing technology, stability durable.

High precision, vibration reduction and pressure reduction, wear resistance, no deformation

High-quality moulds after heat treatment and quenching are more durable.

Various shapes can be bent without changing moulds.

Machine parameters

Max. bending speed | 0.3 s/time |

Max. bending width | 1300mm/1600mm/2000mm |

Bending height | 175 mm |

Average power | 1.5 kw |

Max. bending thickness | UTS 580N/mm2 Stainless steel 1.2 mm |

UTS 410N/mm2 Carbon steel 1.2 mm | |

UTS 265N/mm2 Aluminum 1.2 mm | |

Min. bending thickness | 0.35 mm |

Best Selling

Packing & Shipping

Company Introduction

Nanjing Rongwin machinery technology co.,ltd is located in Zijin Technology Center, Lishui Economic Development Zone,Nanjing,Jiangsu,China (Mainland). Our company is a comprehensive enterprise integrating production and sales. The main products are bending machine and other mechanical equipment, longitudinal shear blades, hobbing scissors, rubber-coated spacers, carbide blades, bending machine die,etc.It is widely used in metallurgy, paper making, printing, forestry hardware, plastics, rubber, metal and other industries.The company's products have won high praise from customers all over the world with high quality and preferential prices. Our company has a strong research and design force, constantly absorbing advanced technology and experience at home and abroad.After years of development, the company with strong technical force, excellent management system, excellent equipment, perfect testing methods, to bring customers real benefits, earlier delivery date and quality assurance. Our company's consistent pursuit is to improve product quality, take science and technology as the spirit, take quality as the guarantee, seek development with products, survive with reputation, perfect quality management system and excellent and thoughtful after-sales service to serve you wholeheartedly.